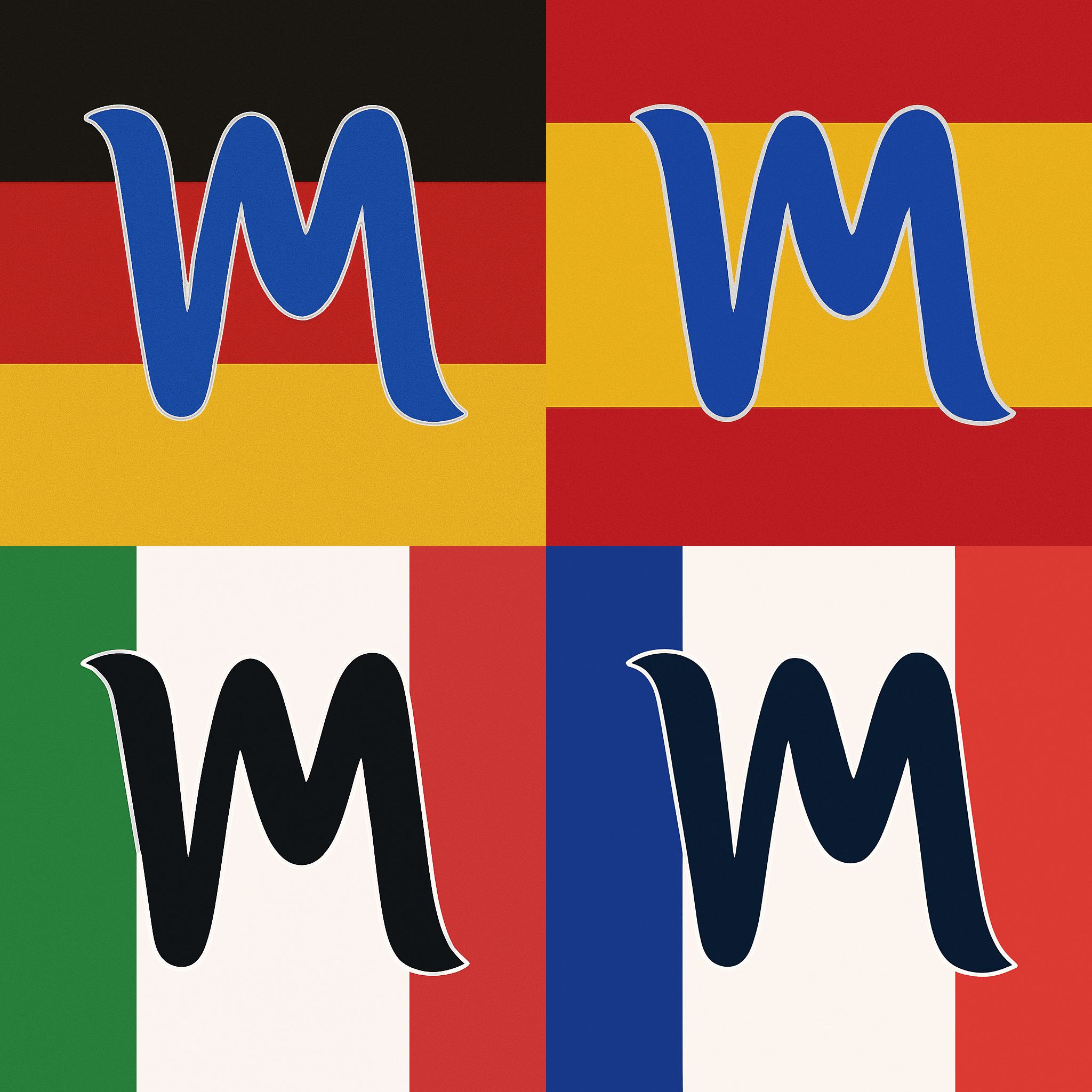

Websites Launched for Germany, Italy, Spain, and France!

Websites Launched for Germany, Italy, Spain, France, Czech Republic, Estonia, Poland, Portugal, Romania, and the UK! We are excited to announce a major expansion of our operations! Vibromera is now even closer to its clients Read more